Magnesium-Aluminum-Zinc Galvanizing

- Super SuperDyma is a type of hot-dip zinc-galvanized steel coil with a galvanization composition of 11% Al, 3% Mg, trace amounts of Si, and the remaining approximately 86% Zn.

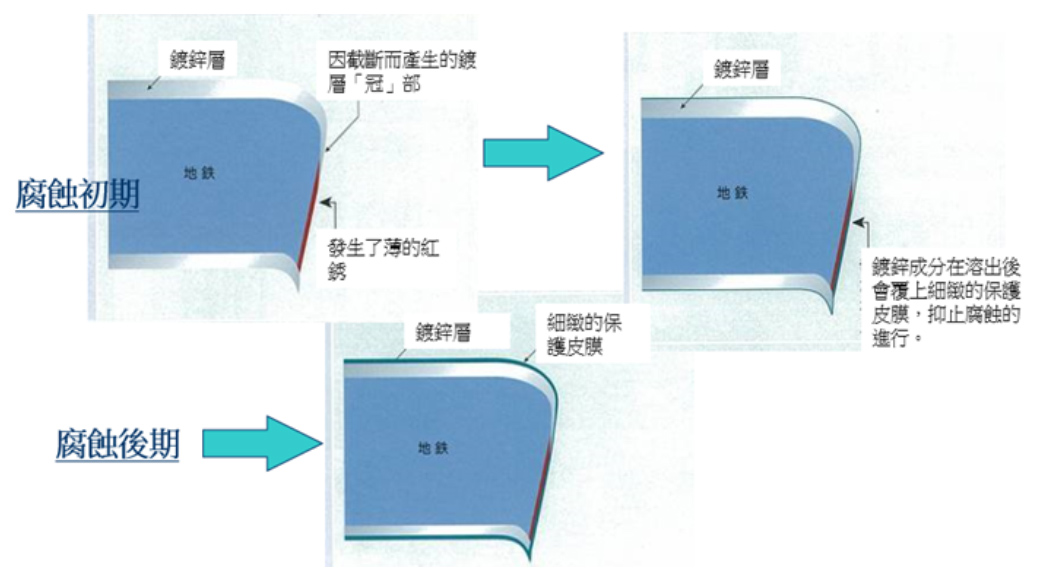

- The composition of this alloy galvanization simultaneously enhances corrosion resistance on flat surfaces and cut edges. The elements in the galvanization dissolve around the cut edges, forming zinc hydroxide, alkaline zinc oxide, and magnesium hydroxide, which provide excellent rust resistance for the cut edges.

- With high corrosion resistance and resistance to alkali (salt damage), it can replace high-cost materials, like stainless steel and aluminum alloys.

- This reduces manufacturing time, eliminates the need for galvanization costs and transportation costs, as well as the time and cost associated with post-galvanizing plug processing.

- Furthermore, it helps prevent deformation as the post-galvanization process involves high temperatures, such as a hot-dip zinc temperature of up to 450 degrees, reducing the chances of deformation when using SuperDyma.

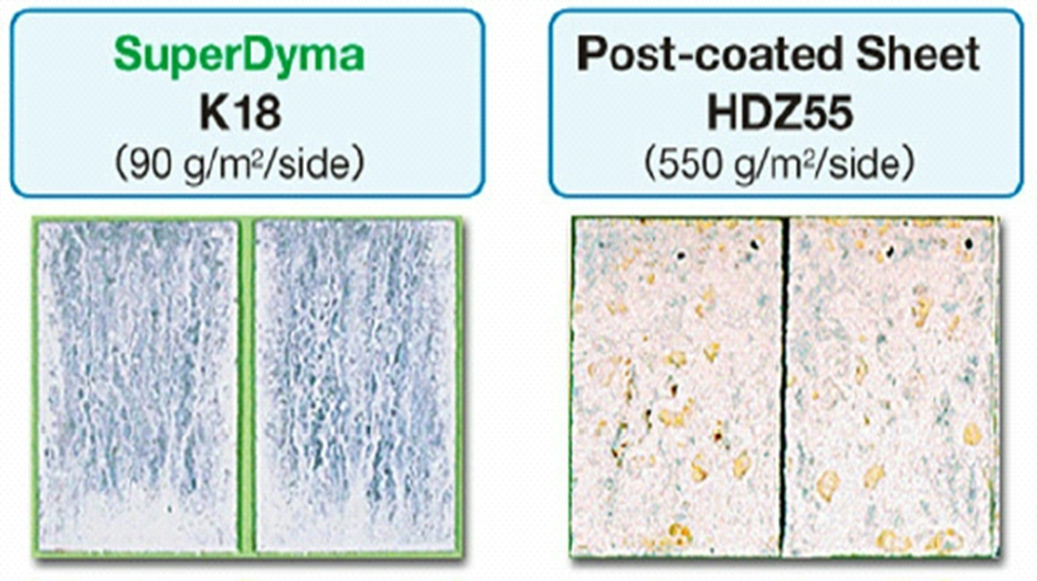

Comparison of SuperDyma and Post-Galvanization Material in Flat Surface Corrosion Resistance

Salt Spray Test Results for 2000 Hours

The post-galvanization material has already shown red rust, while SuperDyma, on the other hand, has not exhibited any signs of red rust.

Corrosion Resistance of SuperDyma's Cross-Section

Range of Applications

- Suitable for coastal areas, livestock areas, agricultural greenhouses, etc.

- General environments: residential, rain shelters, factories, warehouses, roofs, etc.

- Mainly used for solar panel supports, factory walls, and factory roofs.